Waterway hot tub pump rebuild kit for the PF-35-2N22C Massage Master XLT pump used in Beachcomber hot tubs. All parts included in the kit for the wet end are genuine Waterway components. This rebuild kit does not fit the the 48 frame 4.5 hp Waterway pump, EX2 or Viper series pumps

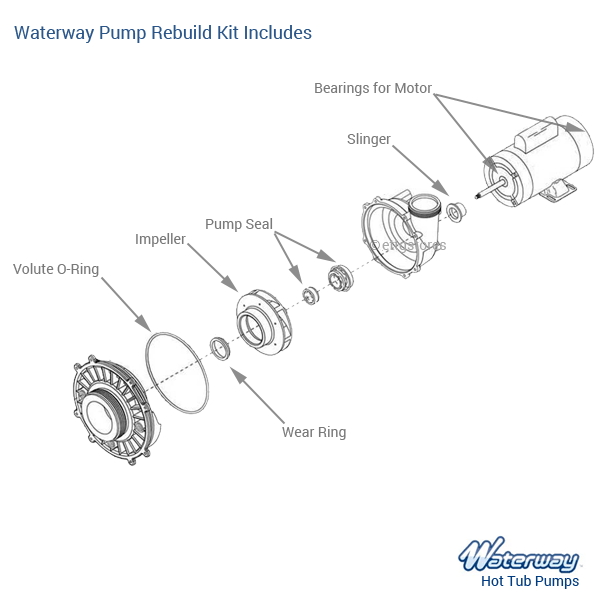

Parts included:

- 1 - O-Ring for the faceplate,

- 1 - Impeller wear ring,

- 1 - Impeller specifically for the PF-35-2N22C

- 1 - Seal kit, professional grade for ozone and saltwater applications

- 1 - Slinger

- 2 - Bearings, 40mm OD, 17mm ID (Shaft size), 12mm wide

- 1 - Tube gasket and O-ring lubricant

- 1 - Seal O-ring

Important Product Notes:

- Seal O-Ring for 315-1260 Volute Required.

Waterway Executive 48 and 56 pumps from around mid 2017 and newer have an upgraded volute which has an o-ring around the seal cup in the volute. Wet ends that have the o-ring around the seal can be identified by the part number 315-1260 W/O on the back of the volute which is visible if looking at the back of the wet end.

- Seal O-ring for 315-1220 Volute Not Required.

Waterway Executive 48 and 56 pumps from around mid 2017 and older have the standard volute which does not have and o-ring around the seal cup in the volute. Wet ends that do not have the o-ring around the seal can be identified by the part number 315-1220 on the back of the volute which is visible if looking at the back of the wet end. Do not use the o-ring on 315-1220 volutes as it will prevent the seal cup from seating properly and may cause damage.

- Fits Waterway pump models from 2010 and newer listed above with first 7 digits of current generation serial numbers starting from PF10277... and up, will not fit pumps with lower or old style serial numbers. Pumps with lower serial numbers or old style serial numbers that start with PF2--, PF3--, PF4-- etc. would need a complete replacement wet end as these parts will not fit.

Replacing the bearings on the hot tub pump motor requires special tools to remove the bearings from the motor shaft as the bearings are pressure fitted (Pressed on the shaft). Attempting to replace the bearings without the proper tools could result is permanent damage to the new parts and motor / pump.